Contact us

Contact:Jerry Jiang

Tel:0086-536-6053990

Fax:0086-536-6053915

Phone:0086-18766363705

ADD: Xiangzhou Industrial Park,Zhucheng City,Shandong Province,P.R.China

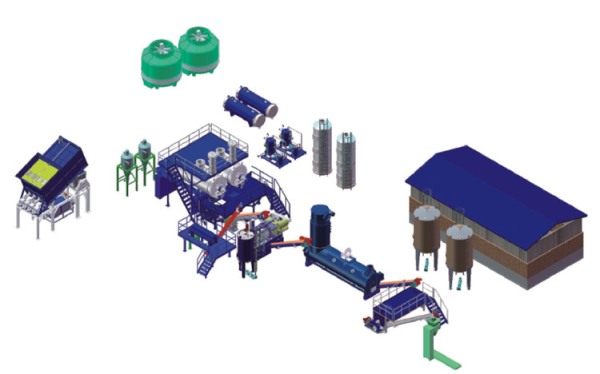

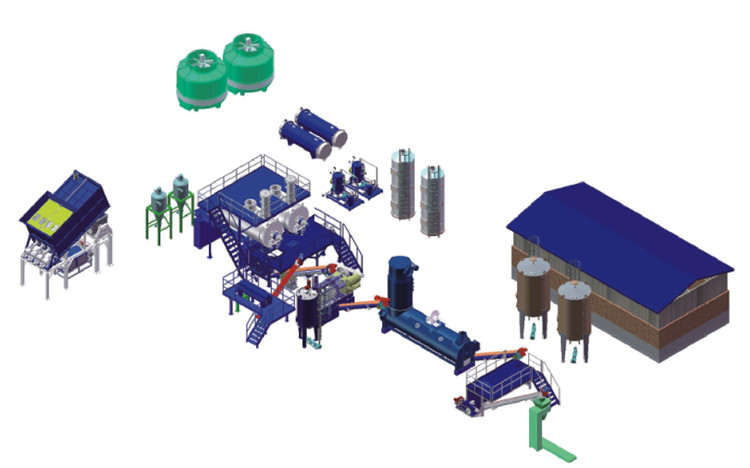

Complete set of equipment for the processing automation, totally enclosed treatment process with no pollution and treatment results for environmental protection, harmless treatment, recycling, high utilization have been concerned. All the units are praised by the users of the unit.

Our machines can turn animal waste and slaughterhouse by-products to valid, for example, turn dead chicken to organic fertilizer and meal for animal feed.

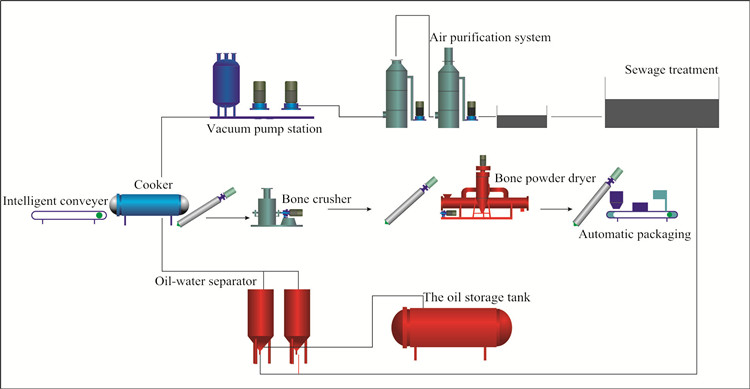

1. Feeding and crushing

The collected animal carcasses are directly dumped into the raw material bin by the dump truck. The screw conveyor at the bottom of the raw material bin pushes the animal carcasses to the crusher which crushes the material into pieces under 50mm. The conveyor conveys the material to the feed pump, and the feed pump conveys the material to the cooking dryer through the closed pipeline.

Bin Pre-breaker

2. Steaming and drying

The weighing system of the steaming and drying machine monitors the feed weight, and ceases feeding when the preset weight is reached. The high-pressure steam in the interlayer and the shaft continuously heats the material to the temperature and pressure set by the process (0.5Mpa, 140°C), and keeps it for 30 minutes. After the pressure is released to normal pressure, the induced draft fan is started and the micro-negative pressure is dried. According to the hygrometer, when the moisture is less than 10%, the drying is ceased, and it takes about 5 hours to transfer the material to the receiving bin. When multiple batches of continuous work are required, start the feeding procedure and enter the next work flow.

Batch cooker Disc Dryer

3. Press degreasing

After the drying is completed, the material has a high fat content. The insulation and heating function of the receiving bin keeps the material at a high temperature. The material is transported to the press through the oil filter screw conveyor. After being pressed by the press, the oil is separated, and after the oil is heated, the impurities in the oil are separated by the solid-liquid separator, and the pure oil is sent to the oil storage tank for storage. The solid protein material enters the powder packaging system for processing.

Oil press

4. Powder packaging

The degreased protein material is in the form of tiles, which are transported to the powder mixer through the cooling screw conveyor, and then crushed into powder by the powder mixer, and then conveyed to the weighing and packaging machine through the screw conveyor to be weighed and packaged.

Packer Milling plant

5. Waste water and waste gas treatment

Establish a complete collection system for the waste water and waste gas generated during the treatment process for centralized treatment.

6. Guarantee and control

Provide guarantee for the electricity, heat source and water of the above five systems. The control system organically connects the above-mentioned five systems, so that the whole process is completed successfully.